Product details page content

Product name

Main performance requirements

When the structural parameters of the oil seal under reliable china oil seal design are determined, the oil seal material is an important factor affecting its sealing performance and service life. It directly affects the three key parameters of the oil seal, namely: the radial force of the shaft to the lip shaft; therefore, the main performance requirements for the oil seal rubber are: ①The chemical stability of the sealing medium is good, and the sealing medium (mainly various oils) does not gum up. Reduced, changing the size of the margin, causing the seal to fail. ②It has good heat resistance and wear resistance, and the friction coefficient is small. This is especially important for oil seals with high line speeds. ③ With moderate elasticity, it can adapt to changes in the roughness and eccentricity of the shaft, and has good follow-up (random) to the dynamic eccentricity.

Formula design points

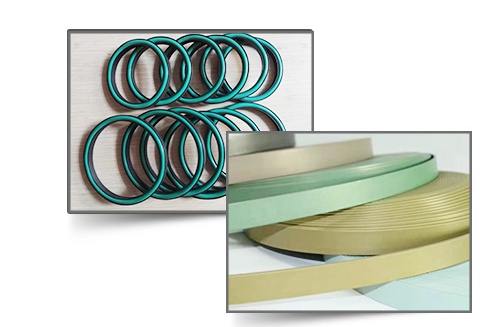

Oil -sealing rubber species are chipped rubber, acrylic vinegar rubber, fluorine rubber and silicon rubber. What rubber is specifically selected, depending on the variety and work temperature of oil. Usually in ordinary fuel, hydraulic oil, motor oil, and lubricant without special additives. When the temperature is -40 ~+ 120 ° C, you can choose chip rubber Rubber; Various oils and corrosive mediums of -40 ~+ 120 ° C can be used in a large medium; fluorine rubber can be used; high temperature and high-speed oil seal at -100 ~+ 250 ° C, silicon rubber can be selected. No matter which rubber is used as the main material of the oil seal, it will cause contraction caused by the expansion of oil and sulfide due to the infiltration of oil. If the oil entering the rubber is more than a lot of components, the vulcanized glue will swell; otherwise, contraction. The shrinking meeting reduces the amount of hypotemporal profits of the lips and shafts, and the randomity decreases. Excessive expansion will change the structure parameter size of the oil seal, reduce the radial force, and cause the seal to fail. Therefore, the volume change rate in the sealing medium should be reduced as much as possible. It is generally believed that the expansion of trace is beneficial to the sealing performance and service life of the oil seal.

① vulcanization system: Dingya rubber should be composed of low sulfur or sulfur -free, or an effective vulcanization system and peroxide. Acrylic rubber is commonly used as a vulcanizing agent for sodium, potassium dumbfaterite, or two. Fluorine rubber generally uses a sulfide of 3#vulcanizers, and for oil seal with high compressed permanent deformation, you can use double -hearted A and radiaxyl tritenal chloride vulcanization system. Silicon rubber still uses sulfide.

② Reinforcement and filling system: The reinforcement agent generally uses the medium particle thermal cracking charcoal black, spray charcoal black or white charcoal black, general charcoal black, semi -supplemental charcoal black, high -resistant carbon black. In order to reduce the friction coefficients of oil sealing rubber, the glue can be equipped with self -lubricating materials such as appropriate amount of graphite powder, memor molybdenum, silicon nitride as filled doses.

③ Plastic measuring agent and aging agent: You should choose a variety that is not easy to be drawn out by sealing medium, such as polyester plasticizers and reactive agents to ensure the stability of the oil seal size, which will not cause excessive contraction, destroy the sealing of the oil sealing sealing sealing performance.