Automotive seals and gaskets may not be the most glamorous components in the automotive world, but they play a vital role in maintaining a vehicle’s performance and reliability. These components have undergone major changes in materials and technology over the years. This article provides an in-depth look at the key differences between traditional gasket materials and modern sealing technologies, focusing on their performance and durability aspects.

Traditional Gasket Materials

materials used in the past

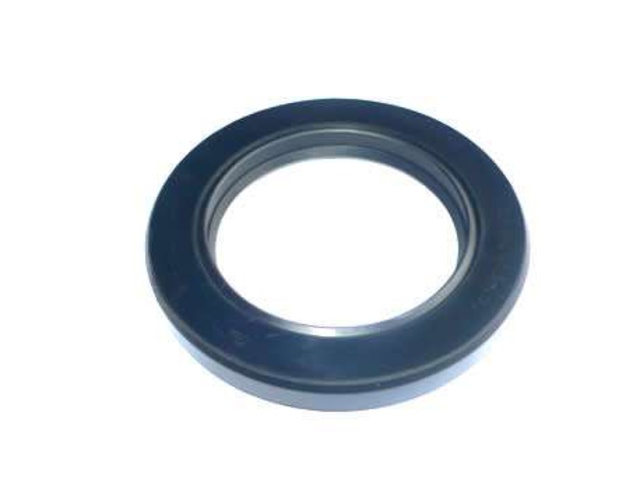

In the early days of automotive engineering, gaskets as car shock absorber sealing products were mainly made of materials such as paper, cork, and rubber. These materials are readily available, cost-effective, and relatively easy to manufacture. Paper gaskets are often used in applications with lower temperature and pressure requirements, while cork gaskets are favored for their compressibility. Rubber gaskets, while more versatile, have limitations in terms of heat resistance and chemical compatibility.

Features and Limitations

Traditional gasket materials have several inherent disadvantages. For example, compression set (the inability to fully rebound after being compressed) is a common problem. Over time, this results in a less effective seal. Additionally, they have limited heat resistance and are not suitable for high temperature applications. Chemical compatibility is another challenge, as exposure to certain fluids can cause gasket materials to deteriorate or swell. These limitations often lead to leaks, performance degradation and increased maintenance needs.

Modern sealing technology

Advanced Materials Overview

As automotive engineering advances, so do the materials and techniques used in the production of gaskets in automotive oil seals. Modern sealing solutions include multilayer steel (MLS) gaskets, synthetic elastomers and high temperature plastics. MLS gaskets combine multiple layers of steel with an elastomeric coating to provide excellent sealing performance and load distribution. Synthetic elastomers, such as silicones and fluorocarbons, offer enhanced chemical resistance and flexibility. High-temperature plastics such as polytetrafluoroethylene (PTFE) perform well in extreme temperature environments.

performance improvement

One of the significant improvements brought about by modern automotive oil seal sealing technology is its enhanced resistance to heat and thermal cycling. For example, MLS gaskets can withstand significant temperature fluctuations without losing seal integrity. In addition, they exhibit improved compression set properties, maintaining their shape and sealing properties over prolonged periods of time and under varying pressure. In addition, modern materials have better resistance to fluids and chemicals, reducing the risk of material degradation due to contact with various automotive fluids.

design innovation

Modern car shock absorber sealing product sealing technology also incorporates innovative design elements. The gasket material features advanced coatings and surface treatments that enhance its durability as well as its resistance to wear and corrosion. Additionally, integrated sealing solutions, where gaskets are designed to fit seamlessly with other components, help improve overall system performance. Together, these design innovations result in a more effective seal, fewer leaks and longer life.

Performance and Durability Comparison

Thermal stability and stress resistance

Comparing traditional gasket materials with their modern counterparts reveals significant differences in thermal stability and stress resistance. Traditional materials often struggle to maintain their sealing properties at extreme temperatures, which can lead to leaks and compromised performance. In contrast, modern materials, especially MLS gaskets and high-temperature plastics, are excellent at maintaining structural integrity even under the harshest thermal conditions. This feature directly translates to improved engine performance and life.

Compression and pressure sealing

Traditional car shock absorber sealing product gasket materials are susceptible to compression set, meaning they can lose their shape and sealing ability after compression. This presents challenges to maintaining a consistent seal, especially in high pressure environments. Modern sealing technologies have enhanced compression set properties that maintain sealing efficiency even when subjected to varying pressure levels. This feature is critical to preventing leaks and maintaining peak performance.

Lifetime and Maintenance Intervals

Traditional gasket materials degrade over time, requiring frequent maintenance and replacement. As these materials lose their sealing properties, leaks can occur, leading to reduced engine efficiency and potential damage. In contrast, modern sealing technologies have a longer service life due to their increased durability. Vehicles equipped with these advanced seals and gaskets require less frequent maintenance, resulting in less downtime and lower maintenance costs over the life of the vehicle.

Practical Applications and Case Studies

Real world applications provide concrete examples of the advantages of modern sealing technology. In engine components, MLS gaskets have proven their effectiveness in maintaining optimum compression ratios, reducing emissions and ensuring consistent engine performance. In high temperature exhaust systems, high temperature plastics have proven their ability to withstand extreme thermal cycling, prevent leaks and maintain exhaust system integrity. These case studies highlight how modern sealing technologies can positively impact automotive systems.

Practical implications and considerations

Cost-effectiveness

While the upfront costs of modern sealing technologies are often higher compared to traditional materials, their long-term cost benefits cannot be ignored. They extend service life, reduce maintenance needs and improve performance, contributing to significant cost savings over the life of the vehicle. This cost-effective perspective encourages manufacturers and vehicle owners to consider the bigger picture when choosing sealing solutions.

Retrofit and Compatibility

An interesting consideration arises when retrofitting older vehicles with modern sealing techniques. While the benefits of upgrading automotive seals and gaskets are clear, compatibility issues can arise. Modern sealing solutions often require corresponding modifications to other components to ensure optimum performance. Manufacturers and mechanics need to carefully evaluate the feasibility and compatibility of such upgrades.

Manufacturer’s and user’s point of view

Original Equipment Manufacturers (OEMs) are increasingly focusing on performance and reliability. Modern sealing technologies align with these priorities as they improve vehicle performance, reduce warranty claims and increase customer satisfaction. From a user perspective, the expectation of a reliable, leak-free vehicle experience makes modern sealing technologies attractive.

Future Trends and Conclusions

As automotive technology continues to evolve, sealing solutions are likely to evolve as well. Emerging materials for efficient car shock absorber sealing products, such as graphene-based composites, could revolutionize the field by offering unprecedented strength, heat resistance, and flexibility. These advances will further blur the lines between traditional gasket materials and modern sealing technologies. In conclusion, the main differences between these two categories of products are their thermal stability, compression characteristics, longevity and overall performance. Selecting the correct sealing solution requires careful evaluation of these factors and an understanding of their impact on automotive system reliability and longevity.

Related Products