Choosing the correct chinese rubber oil seal is a critical part of ensuring machine performance and longevity. With so many options on the market, it can be a challenge to know where to start. In this article, we will discuss the most important factors to consider when selecting a Chinese rubber oil seal, including application requirements, seal material, seal design, seal size, and sealing environment.

application requirements

The first factor to consider when choosing a chinese rubber oil seal is the application requirements. Understanding the application requirements will help you determine the type of High -quality oil seal seal that best suits your needs. There are several key application factors to consider, including temperature, pressure, and velocity.

temperature

The temperature of the sealing environment can have a significant impact on the performance of rubber oil seals. If the temperature is too high, the seal may start to degrade or lose its sealing properties. On the contrary, if the temperature is too low, the sealing ring may become brittle and crack. It is important to select a seal material that can withstand the temperature range of the application.

pressure

The pressure of the sealing environment will also affect the performance of the rubber oil seal. If the pressure is too high, the seal may not be able to maintain a tight seal, resulting in a leak. Conversely, if the pressure is too low, the seal may not be able to maintain contact with the shaft or housing bore, causing premature wear. It is important to select a seal that can withstand the applied pressure.

speed

The speed of the machine will also affect the performance of the rubber oil seal. If the speed is too high, the seals may wear out faster due to friction and heat. Conversely, if the speed is too low, the seal may not be able to maintain contact with the shaft or housing bore, resulting in a leak. It is important to select a seal that can withstand the speed of the application.

Sealing material

The material of the rubber oil seal is another important factor to consider when choosing a chinese rubber oil seal. Depending on the application requirements, different materials have different advantages and disadvantages. Some of the most common materials found in rubber oil seals in China include:

Nitrile rubber (NBR)

Nitrile rubber is a synthetic rubber that is commonly used in oil seals due to its good resistance to oils and fuels. Nitrile rubber is also resistant to water, heat, and abrasion, making it a versatile material.

Fluorocarbon rubber (FKM)

Fluorocarbon rubber, also known as Viton, is a synthetic rubber that is highly resistant to heat, oil and chemicals. Fluorocarbons are often used in high temperature applications where other materials may not be suitable.

Ethylene-propylene rubber (EPDM)

Ethylene propylene rubber is a synthetic rubber commonly used in sealing applications that require resistance to weathering and ozone. EPDM is also resistant to water, steam and some chemicals, making it a popular material for a wide range of industrial applications.

Silicone rubber (VMQ)

Silicone rubber is a synthetic rubber that is commonly used in high temperature applications due to its excellent resistance to heat and cold. Silicone rubber is also resistant to water, steam and some chemicals, making it a popular material for a wide range of industrial applications.

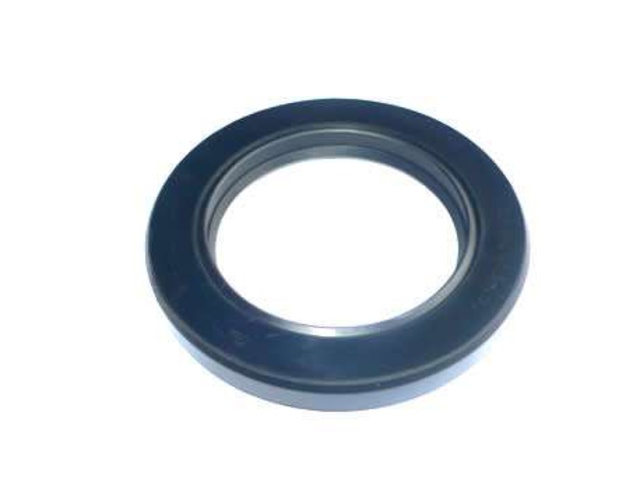

Premium China Oil Seal Design

The design of the rubber oil seal is another important factor to consider when choosing a Chinese rubber oil seal. The design of a seal can affect its performance in several ways, including lip geometry and spring type.

lip geometry

A seal’s lip geometry can affect its ability to maintain a tight seal. Different lip designs are suitable for different applications, depending on factors such as pressure and speed. Some common lip designs include single lip, double lip, and triple lip.

spring type

The spring type of a seal can affect its ability to maintain contact with the shaft or housing bore. Different spring types are suitable for different applications, depending on factors such as pressure and speed. Some common spring types include single springs, multiple springs, and strap springs.

Seal size

The size of the rubber oil seal is another important factor to consider when choosing a China Oil Seal Design. Selecting the correct seal size is critical to ensuring a seal and optimum performance. To determine the correct seal size, you will need to measure the shaft diameter and housing bore.

shaft diameter

To measure the diameter of the shaft, use a micrometer or caliper to measure the diameter of the shaft where the seal will be installed. Be sure to measure the shaft in several points to ensure accurate measurements.

Housing inner diameter

To measure the inside diameter of the case, use an inside gauge or calipers to measure the inside diameter of the case where the seal is installed. Be sure to measure the housing hole in several points to ensure accurate measurements.

sealed environment

The sealing environment is another important factor to consider when choosing a China Oil Seal Design. The sealing environment can affect seal performance in several ways, including temperature, humidity, and exposure to chemicals or contaminants.

temperature

As mentioned earlier, the temperature of the sealing environment will affect the performance of the rubber oil seal. In addition to selecting a seal material that can withstand the temperature range of the application, it is important to consider any temperature fluctuations that may occur during operation. Fluctuations in temperature can cause the seal to expand and contract, affecting its ability to maintain a seal.

humidity

Humidity can also affect the performance of rubber oil seals. In a humid environment, the seal may swell more easily, which may cause it to lose its sealing properties. It is important to choose a sealing material that resists moisture, or take steps to reduce the humidity of the sealing environment.

exposure to chemicals or pollutants

Exposure to chemicals or pollutants can also affect the performance of rubber oil seals. Depending on the application, the seals may be exposed to oils, fuels, solvents or other chemicals that can degrade the seals over time. It is important to choose a seal material that is resistant to the specific chemicals or contaminants the seal will be exposed to.

In conclusion

Choosing the correct China Oil Seal Design is critical to ensuring the performance and longevity of your machine. When selecting a High -quality oil seal seal, it is important to consider the application requirements, seal material, seal design, seal size and seal environment. By considering all of these factors, you can choose a seal that best suits your needs and will provide the best performance and longevity. Remember to accurately measure the shaft diameter and housing bore and select a seal material that will withstand the specific conditions of the sealing environment. With the correct seal, you can ensure a tight seal and reliable performance from your machinery.

Related Products