Introduction

China is a leading Manufacturer of high quality Oil Seals for various industrial applications. China high pressure oil seal is an oil seal specially designed to withstand high pressure applications. Made of high-quality materials, these oil seals provide excellent sealing performance even under extreme conditions.

China has emerged as a major player in the global manufacturing industry. The country’s expertise in producing high-quality and cost-effective products has helped it gain a significant market share in several industries, including the oil and gas sector. The Chinese oil seal design has become popular among oil and gas companies due to its reliability and durability. In this article, we will discuss China’s high-pressure oil seals, their benefits, and how they differ from traditional oil seals.

What is stable China High -pressure Oil Seal

A high pressure oil seal is an oil seal designed to withstand high pressure applications. These seals are used in various industrial applications such as hydraulic cylinders, pumps and other high pressure equipment. High-pressure oil seals are usually made of high-quality materials that can withstand high pressures and temperatures, such as nitrile rubber, Viton or polyurethane.

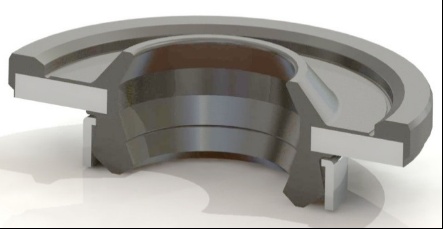

The high pressure oil seal under excellent china oil seal design is designed to provide an effective seal between two surfaces under high pressure environment. It is made of high-quality materials capable of withstanding extreme temperatures, pressures and electric fields. Seals are typically a combination of rubber and metal components engineered to meet the specific requirements of high pressure applications.

The importance of high pressure oil seals

safe High -pressure oil seals are essential components in various industrial applications. These seals are responsible for preventing leaks and protecting high-voltage equipment from damage. Damaged or worn oil seals can lead to equipment failure, downtime and costly repairs. Therefore, it is important to use a high-quality oil seal designed to withstand high-pressure applications.

Types of high pressure oil seals

There are several types of high pressure oil seals on the market. The most common types of oil seals include:

- Piston Seals: Piston seals are used in hydraulic cylinders to prevent leakage and maintain pressure. These seals are designed to fit tightly around the piston and create a barrier between the high-pressure fluid and the cylinder wall.

- Rod Seals: Rod seals are used in hydraulic cylinders to prevent leakage and protect the piston rod from damage. These seals are designed to fit tightly around the piston rod and prevent fluid from leaking from the cylinder.

- Dust seals: Dust seals are used to clean the piston rod and prevent contaminants from entering the cylinder. These seals are designed to remove dirt, dust and other contaminants from the piston rod as it enters and exits the cylinder.

- Guide ring: The guide ring is used to guide the piston rod and prevent it from bending or misalignment. These rings are designed to fit tightly around the piston rod and provide extra support and stability.

Stable China High -pressure Oil Seal Advantages

stable China High -pressure Oil Seal is known for its high quality and durability. Made using advanced manufacturing techniques, these oil seals provide excellent sealing performance even under extreme conditions. Some of the advantages of using Chinese high pressure oil seals include:

- High-quality material: Made of high-quality material, it can withstand high pressure and high temperature. These materials are also resistant to wear, ensuring longer seal life.

- Advanced manufacturing technology: Manufactured using advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), to ensure that the seals are of high quality and meet the required specifications.

- Excellent sealing performance: Designed to provide excellent sealing performance even under extreme conditions. These seals are rigorously tested to ensure they can withstand high pressures, high temperatures and other challenging conditions.

- High cost performance: high cost performance, excellent value for money. These oil seals are priced competitively, making them an affordable choice for businesses that require high quality oil seals for their operations.

The difference between Chinese high pressure oil seal and traditional oil seal

The design of Chinese high-pressure oil seals is obviously different from traditional oil seals. The main difference is the materials used in their construction. The high-pressure oil seal is made of high-performance materials such as polytetrafluoroethylene (PTFE), which has excellent high-temperature and high-pressure resistance. Traditional oil seals are made of nitrile rubber and other materials, which have limited resistance to high temperature and high pressure.

Another notable difference is the design of the sealing lip. The sealing lip of China high pressure oil seal is designed to maintain its sealing ability under extreme pressure difference. Conventional oil seals have a more direct sealing lip design which can lead to oil leakage in high pressure applications.

Application

High-pressure oil seals with excellent china oil seal design are widely used in high-pressure fields. It is commonly used in transformers, generators and electric motors to provide an effective seal between two surfaces. The seal is also used in other high voltage applications such as high voltage cable glands, high voltage switches and high voltage capacitors.

Stable China High -pressure Oil Seal Conclusion

In conclusion, safe High -pressure oil seal is an essential component in various industrial applications. These oil seals are designed to withstand high pressures, high temperatures and other challenging conditions. China high pressure oil seal is made of high quality material and advanced manufacturing process.

Make sure they provide an excellent seal and are durable. These oil seals are available in different types such as piston seals, piston rod seals, wipers and guide rings to meet various industrial needs.

In high pressure applications, it is critical to use high quality oil seals that can withstand extreme conditions. Damaged or worn oil seals can lead to equipment failure, downtime and costly repairs. Therefore, it is crucial to choose a reliable supplier who can provide high-quality oil seals that meet the specifications.

China KNT is a leading manufacturer of high quality oil seals which are used in various industrial applications worldwide. China high pressure oil seals are specially designed to withstand high pressure applications, made of high quality materials and advanced manufacturing techniques.

China high pressure oil seals have multiple advantages, including high-quality materials, advanced manufacturing processes, excellent sealing performance and cost-effectiveness. These oil seals are rigorously tested to ensure they can withstand high pressure, high temperature and other challenging conditions.

safe High -pressure oil seals are essential components in various industrial applications. It is important to choose a reliable supplier that can provide high quality oil seals that meet the required specifications. China is a reliable source for high quality oil seals that provide excellent sealing performance even under extreme conditions. By choosing Chinese KNT high pressure oil seals, businesses can ensure their equipment is free from leakage and damage, thereby improving efficiency and saving costs.

Related Products