Introduction

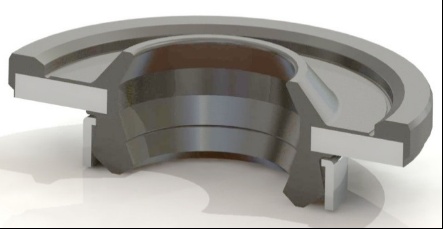

Oil seals play a critical role in keeping machinery running properly by preventing lubricant leakage and contaminants from entering the system. To achieve this, seals must be designed with suitable materials that can withstand operating conditions and provide optimum performance over time. Therefore, the choice of material is an important consideration in china oil seal design.

Factors to be considered in the selection of oil seal materials

Several factors must be considered in the selection of oil seal materials in China. These include operating conditions, compatibility with fluid media and cost.

1. Operating conditions

The first factor to be considered in the selection of oil seal materials in China is the use conditions. Sealing materials must be able to withstand the temperature, pressure and speed of the application. For example, seals used in engines may require materials that can withstand high temperatures without melting or deteriorating. Likewise, seals used in hydraulic systems may require materials that can withstand high pressure and friction.

2. Compatibility with fluid medium

Another important factor to consider when selecting oil seal materials is their compatibility with the fluid media used in the application. Some fluids can cause the seal material to swell or degrade, which can lead to leaks or failure. Therefore, it is important to choose materials that are resistant to chemical breakdown caused by specific fluids.

3. Cost

While performance is critical, cost is also an important consideration when selecting an oil seal material. Generally speaking, the more exotic the material, the more expensive it will be. Therefore, it is necessary to balance performance and cost to ensure that the final product is both effective and affordable.

4. Material selection

Effects on Oil Seal Performance and Durability Material selection can have a significant impact on the performance and durability of Chinese oil seals.

5. Wear resistance

Oil seals are exposed to constant friction which causes wear over time. Material selection affects the seal’s ability to resist wear. Some materials, such as polytetrafluoroethylene (PTFE), have excellent wear resistance due to their low coefficient of friction.

6. High temperature resistance

Seals used in high temperature applications must be made of materials that can withstand extreme heat without melting or losing their sealing properties. Materials such as fluorocarbon rubber (FKM) and silicone rubber are often used in high temperature applications due to their excellent temperature resistance.

7. Resistance to chemical decomposition

Oil seals can be exposed to a variety of chemicals, including fuel, oil, and cleaning agents. These chemicals can cause the seal material to break down, which can lead to leaks or failure. The choice of material affects the ability of the seal to resist chemical breakdown. For example, nitrile rubber (NBR) is resistant to mineral oils, but not certain synthetic oils or fuels.

8. Flexibility and resilience

Sealing materials need to be flexible and elastic to ensure they can maintain a tight seal despite fluctuations in temperature and pressure. Materials such as PTFE and FKM have excellent elasticity and flexibility, making them ideal for dynamic sealing applications.

Examples of commonly used materials for oil seals in my country

Oil seals in excellent china oil seal design usually use several materials. Below are some examples of the most popular materials.

1. Nitrile rubber (NBR)

Nitrile rubber is a synthetic rubber widely used in oil seals due to its excellent resistance to mineral oil and water. It also has good mechanical properties and is relatively inexpensive. However, it is not suitable for use with certain synthetic oils or fuels.

2. Viton (FKM)

FKM is a specialty elastomer with excellent high temperature and chemical resistance. It is commonly used in applications requiring extreme heat resistance, such as automotive engines and aerospace components. However, it is more expensive than other materials.

3. Silicone rubber

Silicone rubber is a synthetic elastomer with good temperature resistance and flexibility. Commonly used in food processing equipment, medical devices and sealing applications where low toxicity is required. However, it does not work with certain chemicals or fuels.

4. Polyurethane (PU)

Polyurethane is a polymer with excellent mechanical properties and wear resistance. It is often used in dynamic sealing applications where high elasticity and wear resistance are required. However, it is more expensive than some other materials.

5. Testing and verification of oil seals in China

To ensure that oil seals meet the required performance standards, they must be rigorously tested and verified. The following are some commonly used detection methods in China.

6. Regulations and standards for oil seal testing

Oil seal manufacturers in China must comply with various regulations and standards, such as ISO9001 and ISO/TS16949. These regulations set out requirements for quality management systems and product testing to ensure that oil seals meet the necessary quality and safety standards.

Oil seal performance evaluation method

Several methods are used to evaluate the performance of oil seals in our country. These include:

- Leak testing: This involves placing the seal in a specific fluid under pressure and monitoring the amount of leakage over time. This test is used to determine whether a seal will maintain a tight seal under specified operating conditions.

- Compression and Recovery Testing: This involves measuring the ability of a sealing material to compress and return to its original shape after being subjected to a specific load. This test is used to evaluate a seal’s ability to maintain a tight seal over repeated cycles.

- Wear and Wear Testing: This involves subjecting the seal material to abrasive materials and measuring the amount of wear over time. This test is used to evaluate the wear resistance of seals.

- Chemical Resistance Testing: This involves exposing the sealing material to a specific chemical and monitoring its response. This test is used to evaluate a seal’s ability to resist chemical breakdown.

In conclusion

Material selection is a key consideration in Chinese oil seal design. Proper selection of materials can significantly affect the performance and durability of oil seals, affecting the effectiveness and life of mechanical components.

Operating conditions, compatibility with fluid media, and cost are important factors to consider when selecting an oil seal material. Additionally, it is critical to balance performance and cost to ensure the end product is both effective and affordable. Rigorous testing and validation procedures are necessary to ensure that oil seals meet the required industry standards and provide a reliable sealing solution.

As technology and innovation continue to advance, so will the selection of materials available for excellent oil seal customization, driving further improvements in performance and durability.

Related Products