Tackling High Temperature Environments: China’s Top Oil Seal Solutions

High temperature environments present a significant challenge for oil seals in various industries such as oil and gas, chemical, and power generation. Oil seals are critical components that ensure the smooth functioning of machinery by preventing leaks and contamination of lubricants. To tackle this challenge, China has developed some of the top oil seal solutions that can withstand high temperatures and ensure uninterrupted machinery operation. In this article, we will explore these solutions and how they can benefit industries operating in high temperature environments.

Understanding the Challenge of High Temperature Environments

High temperature environments pose a significant challenge for oil seals as they can cause seal degradation, leading to lubricant leakage and equipment failure. In industries such as oil and gas, where equipment operates in extreme conditions, failure of seals can result in hazardous situations. Therefore, it is crucial to develop oil seals that can withstand high temperatures and prevent lubricant leaks.

China’s Top Oil Seal Solutions

China has developed some of the top oil seal solutions that can withstand high temperatures and ensure uninterrupted machinery operation. Let’s explore some of these solutions below.

- High-Temperature Resistant Materials

One of the key solutions developed by China is the use of high-temperature resistant materials in oil seals. These materials can withstand temperatures up to 300°C, making them ideal for use in high-temperature environments. The materials used in these seals are typically fluoroelastomers (FKM), perfluoroelastomers (FFKM), and polytetrafluoroethylene (PTFE).

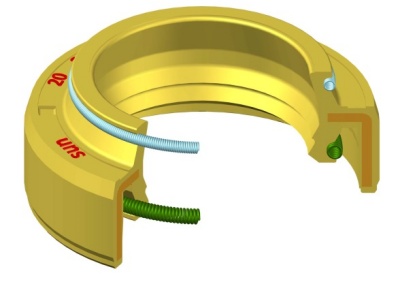

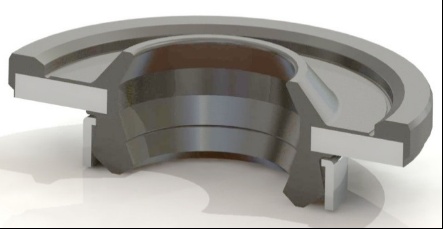

- Advanced Seal Design

China has also developed advanced seal designs that can withstand high temperatures. These seals are designed to prevent lubricant leakage even in extreme conditions. The advanced design includes a metal casing that holds the seal in place and prevents it from deforming under high temperatures. Additionally, these seals have multiple lip designs that can retain lubricants even at high speeds.

- High-Temperature Seal Coatings

China has also developed high-temperature seal coatings that can be applied to standard seals to enhance their high-temperature resistance. These coatings can withstand temperatures up to 400°C and prevent seal degradation. The coatings are typically made of high-temperature resistant materials such as ceramics and metal oxides.

- Customized Seals

China also offers customized oil seals that can be designed to meet specific high-temperature requirements. These seals are designed to fit the exact specifications of the equipment, ensuring optimal performance. The customization includes material selection, seal design, and seal coatings.

- Performance Testing

China also offers performance testing services for oil seals to ensure their effectiveness in high-temperature environments. The testing includes high-temperature endurance testing, vibration testing, and pressure testing. These tests ensure that the seals can withstand high temperatures, pressure, and vibrations without failure.

Benefits of Using China’s Top Oil Seal Solutions

Using China’s top oil seal solutions can offer several benefits for industries operating in high-temperature environments. Some of these benefits include:

- Enhanced Equipment Performance

China’s top oil seal solutions can improve equipment performance by preventing lubricant leakage and contamination. This, in turn, can reduce equipment downtime and maintenance costs.

- Improved Safety

Using high-temperature resistant oil seals can enhance safety in hazardous environments such as oil and gas. The seals prevent leaks that can cause fires and explosions, ensuring worker safety.

- Customization

China’s customized oil seals can be designed to fit specific equipment requirements, ensuring optimal performance.

- Cost-Effective

Using China’s top oil seal solutions can be cost-effective in the long run as they can reduce equipment downtime and maintenance costs.

Conclusion

High temperature environments present a significant challenge for oil seals, but China has developed some of the top oil seal solutions that can withstand extreme temperatures. These solutions include the use of high-temperature resistant materials, advanced seal designs, high-temperature seal coatings, customized seals, and performance testing. These solutions offer several benefits for industries operating in high-temperature environments, including enhanced equipment performance, improved safety, customization, and cost-effectiveness. By utilizing China’s top oil seal solutions, industries can ensure uninterrupted machinery operation and prevent hazardous situations.

In summary, the development of top oil seal solutions in China showcases the country’s commitment to innovation and meeting the needs of various industries. With the ever-increasing demand for machinery to operate in extreme conditions, the importance of oil seals that can withstand high temperatures cannot be overstated. China’s top oil seal solutions provide a reliable and effective way to tackle the challenge of high-temperature environments, ensuring equipment performance and worker safety.

Related Products