For chinese rotation oil seals play a key role in a variety of applications including the automotive, machinery, aerospace and marine industries. They are designed to prevent fluid or lubricant leakage from rotating shafts, protecting equipment from damage and ensuring optimum performance.

China rotary oil seals are essential components that fulfill a critical function across a wide range of industries, including automotive, machinery, aerospace, and shipbuilding. These seals are specifically engineered to prevent the leakage of fluids or lubricants in rotating shafts, providing vital protection to equipment and ensuring optimal performance.

In the automotive industry, China rotary oil seals find extensive usage in engines, transmissions, and other rotating components. They effectively seal the gaps between the rotating shafts and housing, preventing the escape of lubricating oils and fluids. By maintaining the integrity of the sealing system, these oil seals contribute to the smooth operation and longevity of the engine and its various mechanical components.

In the machinery sector, China rotary oil seals are integral to the proper functioning of heavy-duty equipment, such as pumps, compressors, and gearboxes. By forming a reliable barrier against fluid leakage, these seals help to preserve the efficiency and reliability of these vital machines. They prevent contaminants from entering the system, safeguarding sensitive internal components and reducing the risk of equipment failure or downtime.

China rotary oil seals also play a crucial role in the aerospace industry, where they are utilized in aircraft engines, turbines, and other rotating systems. These seals ensure the containment of vital fluids, such as jet fuel and lubricants, within the designated areas, promoting safety, efficiency, and the overall performance of aircraft systems. Their ability to withstand high temperatures, extreme pressures, and demanding environmental conditions makes them indispensable in the aviation field.

Performance of Chinese rotary oil seal

Sealing performance

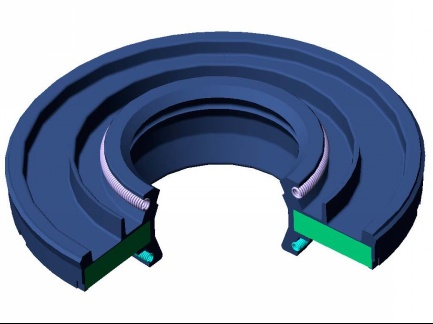

The main function is to prevent fluid or lubricant leakage from the rotating shaft. The sealing mechanism of the Chinese rotary oil seal includes a sealing lip that is in contact with the rotating shaft to form a seal that prevents fluid leakage. The sealing performance of this oil seal is affected by several factors including lip material, lip geometry and spring design.

Leak-Proof: Designed to be leak-resistant, which is critical to preventing equipment damage. The sealing lip must always be in contact with the rotating shaft to maintain a tight seal. Lip material and geometry must be carefully selected to provide the necessary sealing performance.

wear resistance

Exposure to high levels of friction and wear, which can lead to premature failure. The wear resistance of oil seals is affected by material selection and surface finish.

- Material Selection: Materials must be able to withstand high levels of friction and wear. Commonly used materials are nitrile rubber, silicone rubber and fluororubber. Each material has unique properties that make it suitable for different applications.

- Surface finish: The surface finish of the rotating shaft and housing is also essential for wear resistance. Surfaces must be smooth and free of defects to prevent excessive seal wear.

Temperature resistance

It must be able to withstand a wide temperature range without losing its sealing properties. The temperature resistance of Chinese rotary oil seals is affected by the operating temperature range and heat dissipation.

- Operating temperature range: The temperature range of the application is an important consideration when choosing a Chinese rotary oil seal for automobile shock buffer. If the temperature exceeds the upper limit of the seal, it will cause the sealing material to degrade, reducing its effectiveness. On the contrary, if the temperature is lower than the lower limit, the seal will become brittle and lose its function.

- Heat dissipation: The heat generated by the rotating shaft will also affect the temperature resistance of Chinese rotary oil seals. The design of the seal must allow for proper heat dissipation to prevent damage to the seal.

Application

Automobile industry

- In the automotive industry, used in engines and transmissions to prevent oil and other fluid leakage. They are critical components to ensure optimum performance and longevity of your vehicle.

- Engine System: Used in engine systems to prevent oil leakage from the crankshaft, camshaft and other components. They must be able to withstand high temperatures and pressures, as well as the high speed of rotation of the engine.

- Transmission system: Also used in the transmission system to prevent transmission fluid leakage. They must be able to withstand high temperatures and pressures, as well as the speed of the transmission.

Mechanical Engineering

- In the machinery industry, used in a variety of equipment, including construction and agricultural machinery, to prevent leakage of hydraulic oil, lubricating oil and other fluids.

- Construction Equipment: Used in construction equipment such as excavators and bulldozers to prevent hydraulic oil leakage. They must be able to withstand high pressures and harsh operating conditions.

- Agricultural Equipment: Also used in agricultural equipment such as tractors and harvesters to prevent leakage of hydraulic oil and lubricating oil. They must be able to withstand the high demands of agricultural applications.

other industry

- Aerospace: In the aerospace industry, used in engines and other critical components to prevent fluid leakage. They must be able to withstand extreme temperatures and pressures, as well as high-speed rotation of components.

- Marine: In the marine industry, for engines and other equipment to prevent leakage of lubricating oil and other fluids. They must be able to withstand harsh marine environments, including exposure to salt water and other corrosive elements.

Comparison with other types of oil seals

The Chinese rotary oil seal is one of several oil seals available in the market. Comparing with other types of oil seals is essential to understand their pros and cons.

- Radial Oil Seals: Radial oil seals are similar to Chinese rotary oil seals, but are designed for stationary applications. They are used to prevent fluid leakage from stationary shafts and housings. Radial oil seals are easier to install than this one, but are not suitable for rotating shafts.

- Axial Oil Seals: Axial oil seals are used to prevent fluid leakage from axial movement, such as in hydraulic cylinders or pistons. They are not suitable for rotating shafts and have a limited range of applications compared to this oil seal.

- Non-contact seals: Non-contact seals, such as labyrinth seals and magnetic seals, do not come into contact with the rotating shaft. Instead, they form a barrier that prevents fluid from leaking out. Non-contact seals are suitable for high-speed applications, but are not as effective at preventing leakage as Chinese rotary oil seals.

Factors to consider when choosing

Several factors must be considered when selecting a Chinese rotary oil seal, including shaft and housing material, seal lip design, spring design, and seal size and installation.

- Shaft and housing material: The material used for the shaft and housing can affect the performance of the rotary oil seal. The surface finish of the shaft and housing must be smooth and free of defects to prevent excessive seal wear.

- Sealing lip design: The design of the sealing lip will affect the sealing performance of the Chinese rotary oil seal. Lip geometry must be carefully selected to provide the necessary sealing performance.

- Spring Design: The spring that holds the sealing lip in place must be designed to provide the necessary sealing force while still allowing proper movement of the lip.

- Seal Size and Installation: Seal size must be carefully selected for proper shaft and housing installation. Proper installation is also important to ensure optimum performance and prevent premature failure.

Common Failure Modes and Prevention Strategies

Can fail due to a number of factors including wear, leaks, hardening and cracking. Prevention strategies must be in place to prevent premature failure and ensure peak performance.

- Wear: Excessive friction between the seal lip and the rotating shaft or housing can cause wear. Proper material selection and surface finish can help prevent excessive wear.

- Leaks: Damaged or improperly installed sealing lips can cause leaks. Proper installation and regular inspections help prevent leaks.

- Hardening and Cracking: Hardening and cracking may occur due to exposure to high temperatures or harsh chemicals. Proper material selection and regular inspection can help prevent hardening and cracking.

In conclusion

For chinese rotation oil seal is a key component that plays a vital role in various applications in different industries. Their sealing properties, wear resistance and temperature resistance make them ideal for preventing fluid leakage from rotating shafts. Proper material selection, seal lip design, spring design and installation are important factors that must be considered when selecting this oil seal. Regular inspection and maintenance help prevent premature failure and ensure peak performance. China’s rotary oil seal industry has broad prospects, technology and materials continue to improve, and performance and applications are further improved.

Related Products